The term cement power resistor refers to a design and construction method of producing wire wound resistors and power resistors. This method of construction has been used for over 70 years and is still widely used today to produce resistors with these characteristics:

- high reliability

- low cost production

- stable temperature performance

- compact design

- wide range of power ratings possible

- resistance tappings possible

- ease of mounting and a variety of types of mounting brackets available

Construction Of Cement Filled Resistors

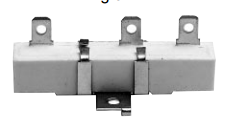

A cement filled wire wound resistor

The above image shows a PW50 50 watt wire wound resistor. The resistance winding is encased in a rectangular ‘ceramic boat’. Once the winding is placed into this ‘boat’ it is then filled with a cement material that has stable mechanical and electrical (insulation) properties. By having a range of different sized ‘ceramic boats’ available (as shown in the image below), we can manufacture a wide range of different power rated power. resistors.

The manufacturing of this style of resistors is relatively ‘low cost’ meaning that it is possible to manufacture a range of highly reliable resistors in a range of resistances and power ratings that meet the needs of a wide range of industries. Details on our PW range of flameproof resistors can be found here.