Australian Resistors supplies a wide range of both fixed and variable wire wound resistors, power resistors and custom resistor assemblies for any application. CALL NOW ON 0428261110. FAST DELIVERY, NO MINIMUM ORDER QUANTITY FOR MOST PRODUCTS.

Wire Wound Resistors and Power Resistor Supplier: Australian Resistors

Australian Resistors is a long established supplier of resistors in Australia and our history as a local manufacturer of wire wound resistors stretches back over 50 years. We proudly service customers all around Australia as well as overseas. We have a strong, ongoing commitment to supplying quality products to our customers including many high profile Australian manufacturers and Government organisations. We are able to offer very short turn around times for most wire wound resistors and power resistors. Call us on 0428261110 for fast service and technical support.

Product Range – Overview

We have a very diversified resistor product range to meet your specifications. A brief overview of our products follows. Visit the Products page for further details and links to data sheets. If the resistor product you require is not listed here, please contact us and will will be happy to try and assist you.

Rheostats

Our rheostat APR series range comes in 5 power ratings – 25 Watt, 50 Watt, 150 Watt, 300 Watt and 500 Watt. They are extremely well made, exhibit excellent heat dissipation characteristics and are very reliable high power variable resistor – there are many thousand of them being used in industrial applications around Australia and the world. They come in a variety of terminations and have an ‘off’ option available. Full data here.

made, exhibit excellent heat dissipation characteristics and are very reliable high power variable resistor – there are many thousand of them being used in industrial applications around Australia and the world. They come in a variety of terminations and have an ‘off’ option available. Full data here.

Power Wire Wound Resistors

Our Tubular Wire Wound High Power resistors are available in fixed resistance values, adjustable or tapped  resistances depending on your requirement. The power ratings available range from 20 watts up to 1200 watts. These resistors offer excellent resistance to moisture and the unique coating technology ensures high reliability and long life. They can be supplied in tolerances from 1% to 10% depending on the value. Many clients have the need to adjust the value of the resistors ‘in-situ’ and the adjustable option is ideal for these applications. When you buy our power resistors you are purchasing a quality product. Full data here.

resistances depending on your requirement. The power ratings available range from 20 watts up to 1200 watts. These resistors offer excellent resistance to moisture and the unique coating technology ensures high reliability and long life. They can be supplied in tolerances from 1% to 10% depending on the value. Many clients have the need to adjust the value of the resistors ‘in-situ’ and the adjustable option is ideal for these applications. When you buy our power resistors you are purchasing a quality product. Full data here.

Precision Wire Wound Resistors

The ASW series resistors offer tolerances up to 1% by using precision winding techniques.  They are very suitable for designs and applications requiring high reliability and have ratings of 1.5 watts (ASW 1), 3.0 watts (ASW2 series), 6.5 Watts (ASW5 series), 8 Watts (ASW7 series) and 11 watts (ASW10 series). They have excellent impulse tolerance characteristics and are used in applications ranging from current limiting resistors to current sense resistors to circuitry needing to withstand high voltages. Full data here.

They are very suitable for designs and applications requiring high reliability and have ratings of 1.5 watts (ASW 1), 3.0 watts (ASW2 series), 6.5 Watts (ASW5 series), 8 Watts (ASW7 series) and 11 watts (ASW10 series). They have excellent impulse tolerance characteristics and are used in applications ranging from current limiting resistors to current sense resistors to circuitry needing to withstand high voltages. Full data here.

Flameproof Power Resistors

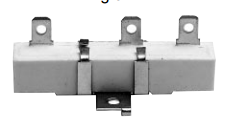

The industry standard PW series of resistors come in 20 Watt and 50 Watt versions and offer an economical and  very versatile design suited for household appliances like range hoods, heating and cooling systems and many other applications. Their ceramic ‘boat’ and non flamable construction lends itself to situations where a fireproof resistor is required. They also work well in high temperature environments and have been used extensively by many large Australian appliance manufacturers for more than 20 years. These resistors can be supplied with a tapping to your specification and come in a number of versatile mounting options and configurations. Full data here.

very versatile design suited for household appliances like range hoods, heating and cooling systems and many other applications. Their ceramic ‘boat’ and non flamable construction lends itself to situations where a fireproof resistor is required. They also work well in high temperature environments and have been used extensively by many large Australian appliance manufacturers for more than 20 years. These resistors can be supplied with a tapping to your specification and come in a number of versatile mounting options and configurations. Full data here.

Current Sense Resistors

We are able to design and supply a wide range of P.C.B. mounted wire frame current sensing resistors. Ideal for power supply and motor control applications to name a few, these resistor assemblies are economical yet extremely reliable. Full data here.

mounted wire frame current sensing resistors. Ideal for power supply and motor control applications to name a few, these resistor assemblies are economical yet extremely reliable. Full data here.

Adjustable Resistors

We can supply many of of range of wire wound and power resistors as an adjustable resistor. This is very convenient for applications requiring ‘in-circuit’ adjustment of the resistance value of the power resistor. Contact us for helpful assistance.

Low Profile ‘Flat’ Wire Wound Power Resistors

The FRW series is a uniquely designed power resistor offering a low profile and very compact design for applications where mounting space may be limited yet a requirement for high power dissipation exists. This very versatile power resistor is available from 20 watts up to 75 Watts and the design lends itself to ‘stacking’ of the resistors – via specially designed spacing sleeves, meaning several FRW resistors can be installed in a compact area with ease. Options are available for tappings and adjustable versions. The FRW series resistor can be supplied to a 1% tolerance, with the standard tolerance being 5%. Full data here.

where mounting space may be limited yet a requirement for high power dissipation exists. This very versatile power resistor is available from 20 watts up to 75 Watts and the design lends itself to ‘stacking’ of the resistors – via specially designed spacing sleeves, meaning several FRW resistors can be installed in a compact area with ease. Options are available for tappings and adjustable versions. The FRW series resistor can be supplied to a 1% tolerance, with the standard tolerance being 5%. Full data here.

Y Series 500 Watt to 1000 Watt Power Resistor Assembly

The Y Series was designed for high power resistor requirements up to 1000 Watts. Designed to absorb a short time  overload of 5 times their rated load and unaffected by most common solvents this resistor is ideal for demanding industrial applications. They employ rod mounting via an M8 thread 100mm longer than the ceramic length and are fixed with M8 locknuts. Optional horizontal mounting feet are available. Full data here.

overload of 5 times their rated load and unaffected by most common solvents this resistor is ideal for demanding industrial applications. They employ rod mounting via an M8 thread 100mm longer than the ceramic length and are fixed with M8 locknuts. Optional horizontal mounting feet are available. Full data here.

Open Wire Resistors

Typically used in banks for braking applications on heavy equipment. Full data here.

Metal Clad Resistors

Ranging from 5 watts to 250 watts this versatile range of aluminium housed resistors are small in size, offer  precision windings and have a non inductive winding option. Full data here

precision windings and have a non inductive winding option. Full data here

Note: as of May 2021 we are now able to offer the SMRH series of High Power Metal Clad wire wound resistors with power ratings from 60 watts to 1000 watts. Full data here.

Resistors – Characteristics and Specification

Selecting the correct resistor for your application is important. Understanding some of the often complex factors that go into resistor construction and how various characteristics of resistors are specified is useful in ensuring correct component selection.

Parameters In Power Resistor Specification and Selection

Temperature Derating

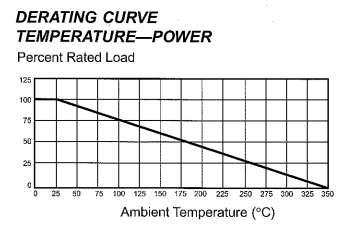

The power rating for resistors is generally specified at 25 degrees C (ambient) and it is important to understand when designing circuitry that a derating factor applies as temperature increases. For example, the precision wound series of resistors derate to 75 percent of their rated load at 100 degrees C and 50 percent at 175 degrees C. This can be an important consideration in some industrial applications where equipment housing these resistors may be located in areas (like blast furnaces, for example) that experience high ambient temperatures. If this is the case, a higher wattage resistor may be more appropriate than the initial power calculations suggest. Most resistor data sheets specify the temperature range that the resistors will operate under. For wire wound resistors this is typically -55C to +275 C, but varies depending on the physical construction of the resistor, its coating material and surface area. Ratings are generally specified ‘suspended in free air’ and taking into account the effect of any enclosing structure around the resistor assembly is an additional factor you should consider when determining power rating selection. The linearity of the derating is typically quite linear for wire wound resistors as is shown on the derating graph for the precision wound resistor range.

Resistor Coatings And Derating

Many tubular wire wound resistors are manufactured by applying a resistance winding onto a tubular ceramic former (as is the case with the power wire wound resistor range). A coating material is then applied (generally several coats) to the resistor which effectively ‘seals’ the completed assembly and ensures long term reliable operation in high humidity environments and the mechanical integrity of the structure. Coating materials are generally silicon based and have been used in this application for many years with long term reliability. Different coating materials applied to the resistors have different effects on the temperature derating factor of the resistor. Different coatings can exhibit as much as a 50% reduction in specified power ratings.

Maximum Voltage Across Resistor Rating

This can be an important factor when selecting the most appropriate resistor for a particular application particularly where high voltages are concerned. The maximum voltage across a resistor is calculated a the square root of the rated wattage of the resistor, multiplied by its resistance value.

Example: 33 ohm, 100 watt power resistor. The maximum voltage across this resistor would be calculated as follows: √( 33 x 100) = 57 volts.

Power Rating

The power rating of a resistor is calculated as the square of the current multiplied by the resistance. (I ² x R , where I=current and R=Resistance). As discussed above, factors including temperature rating and maximum withstand voltage need to be considered when determining the correct power rating of a resistor for a specific application.

Termination Onto Power Resistors and Mounting Considerations

Because of the nature of construction of wire wound resistors, the electrical connection onto the resistor assembly can be an important consideration to ensure:

- Ease of assembly into the finished product

- Long term electrical reliability of the equipment

- Mechanical mounting considerations. For example some resistor assemblies are designed for ‘snap fit’ ferrule mounting

Methods of termination onto the resistor assemblies can include

- Quick connect terminals employing standard 6.3mm spade lugs

- Flying leads

- Edison base – allowing for ‘screw in’ termination

- Nut and bolt through terminal termination

- Solder terminals

Mounting Of Resistor Assemblies

Given that large power resistors can be substantial in size, for example the YM series 1000 watt resistor has an ceramic length of 475mm, mounting considerations, ensuring mechanical integrity and air flow around the resistor are important issues. Mounting methods can include:

- Threaded rod mount with lock nuts to ensure rigidity and security of large mass power resistors

- Mounting ‘feet’ for tubular ceramic wire wound resistors. Plated metal mounting feet inserted into the ceramic former make for ease of mounting.

- Ceramic ‘boat’ style resistors can have a variety of mounting options including standard and custom brackets mounted to the ceramic body of the resistor. The brackets can allow for both horizontal and vertical mounting of the resistor assembly as shown below:

Average Temperature Rise Versus Load

Understanding the relationship between resistor surface temperature (and hence radiated heat) versus the percentage of rated load is important as it can be helpful in the specification and selection of the most appropriate resistor and in its temperature performance in the finished product. The relationship between average temperature rise for the resistor suspended in free air versus the percentage of rated load if fairly linear as the following chart examples for rheostats and power resistors demonstrate:

Rheostat Chart – Average Temperature Rise Versus Load

Power Resistor Chart – Average Temperature Rise Versus Load