Selecting the correct wire wound resistor for your application is critical in insuring excellent long term reliability for your circuitry and equipment in which the power resistor is being used. Once you have determined the appropriate power rating for your application, by, for example, using ohms law, you can then select the type of resistor based on these parameters:

- Physical size

- Required method of mounting the resistor

- Electrical pulse handling capability

- Requirement of the resistor to be adjustable or fixed in value

- Required tolerance of resistance

- Mechanical construction of the resistor

- Non Inductive winding

As you will see from the products page, we can offer a resistor that will meet virtually any specification for wire wound or power resistor. Over the next few months we will look at examples of selecting the appropriate wire wound resistor include:

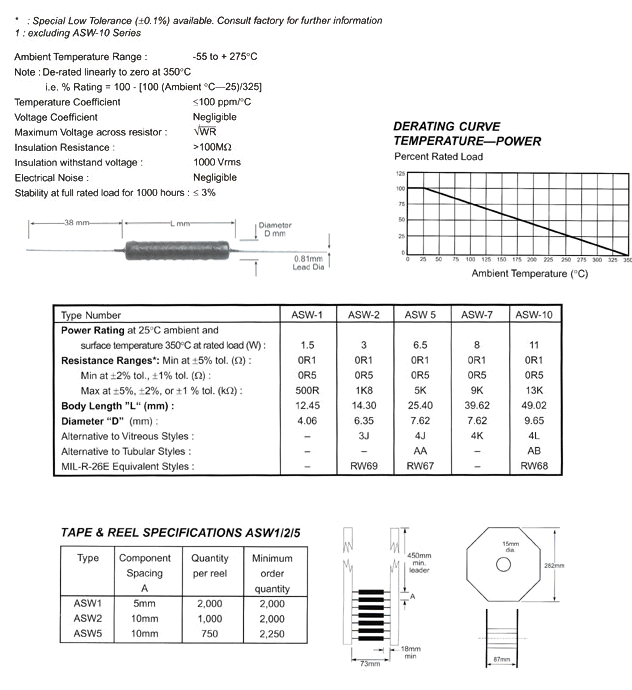

Example 1. Requirement is a 10 watt rated, non inductive power resistor with a tight 1 percent resistance tolerance and a printed circuit board mounting preference. The ASW 10 wire wound resistor meets these requirements. It has an 11 watt rating (so slightly ‘over rated’), comes with an option of a non inductive winding, has a 1 percent tolerance available on the winding and comes with rugged welded axial leads which are ideal for printed circuit board mounting. Beacause of the ‘D’ coating material applied to the resistor after winding, the high temperature performance including the electrical ‘stability’ of the resistor is excellent and it has a proven track record of high reliability over more than 40 years.

ASW Series Wire Wound Resistor Data: